|

Crate Remote Control |

||||||

|

Crate Remote Control |

||||||

Introduction to the CAN-BusThe Controller Area Network (CAN) defined by Bosch in 1985 is an advanced serial multimaster communication protocoll. Due to the reliability and technical capability as well as to the available low-price system components CAN is well suited for application in fieldbus system. The most important features of CAN are:

|

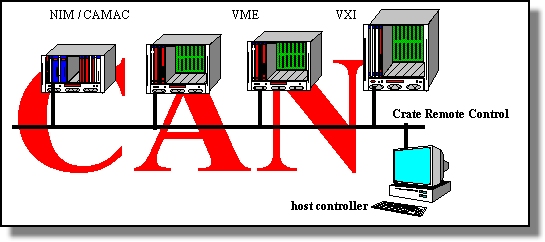

Crate remote Control via CAN-busBased on the WIENER µ-processor controlled intelligent fan-tray-units equipped with the WIENER CAN bus interface this remote control can be integrated within an CAN fieldbus system. Up to 126 crates can be controlled within a network. In addition to the remote on/off and SYSRES (VME) the user can control and program remotely every crate parameter via the interface as (* in progress):

|

|

Powered Crates | Accessories | Power Supplies | Sales Net | Home | Company Info

This page was created by W-IE-NE-R, A&K.Ruben - 9/98